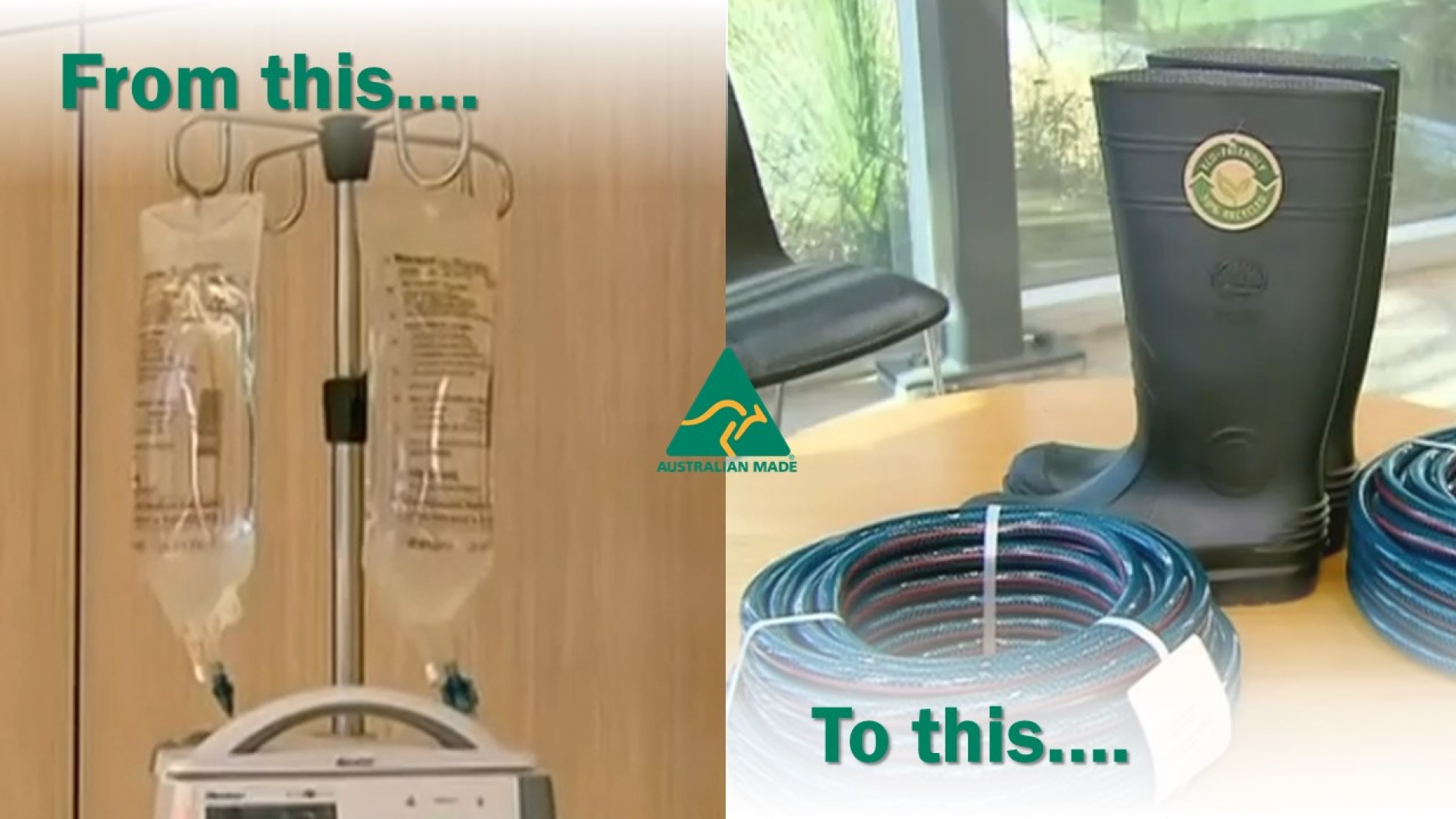

Creating a circular economy for PVC through industry and stakeholder collaboration requires transformation in the way PVC products are designed, produced and used. Ongoing progress towards this goal was revealed by a host of global experts at PVC AUS 2022: Shared Horizons.

Organised by the Vinyl Council of Australia (VCA), the two-day Gold Coast, Queensland conference brought together over 130 delegates from Australasia’s vinyl value chain to discuss key trends, issues and sustainability challenges influencing the region’s PVC sector.

Major topics included collaboration with industry, government and stakeholder groups to find solutions to PVC circularity and reinforce the material’s role in a circular economy. This included the challenge of transitioning to lower carbon PVC products, avoiding substances of high concern and shifting local uPVC window production to the next level covered by a range of local and international expert speakers.

The event was supported by headline sponsors Formosa Plastics Corporation, a vertically integrated supplier of plastic resin, fibre and petrochemicals, plastics extrusion technology leaders Battenfeld-Cincinnati and Greiner Extrusion GmbH, and powder handling specialists Idealtec.

In his opening address, VCA Chairman Matthew Hoyne highlighted how their 20-year-old PVC Stewardship Program (PSP) remains a valuable program for a circular economy, with 50+ signatory companies engaged with the Vinyl Council’s aims of advancing sustainable development of the industry.

“Our PVC Stewardship Program led the industry in addressing upfront material design issues – reducing emissions and avoiding mercury, lead and cadmium, and more recently low molecular weight phthalates. It has also encouraged industry to start addressing greenhouse gas emissions and the minimisation of production waste to landfill and uptake of PVC recyclate in products, as well as transparency in the discussion of issues across the supply chain,” he said.

Gerhard Hoffman, Head of Product Design and Innovations at Greiner Extrusion outlined the world market for uPVC windows and lessons for Australian industry growth, pointing out PVC windows’ popularity in Europe is due to their low thermal conductivity leading to higher performing windows.

Forecasting future uPVC profile designs, he explained: “The game changer will be U-value. Australia has one of the highest minimum required U-values in the world (the lower the U-value, the more thermally-efficient the window): the ideal window for our climate would have a U value of 1.5 for optimum thermal efficiency.”

While in 2006 uPVC windows had a market share of just 1.6% in Australia, by 2021 that had increased to 8.8%, and Gerhard saw much more possibility for growth in the coming years. He added: “I see a potential for 7.7 million window units in Australia based on the population, while currently there are only 4 million window units.”

In her perspective on changing perceptions for a more sustainable future, Cindy Bray from the Plastics Industry Pipe Association of Australia (PIPA) updated delegates on their Construction Plastics Recycling Scheme supported by the Queensland Government.

“Construction waste and building demolition are the prime opportunities for recovery of PVC piping for recycling and re-use,” she observed. “Six months on, all stakeholders are keen to continue and expand the scheme.”

Lessons from developing a circular economy for resilient floorcoverings in Europe was covered by Jane Gardner of the European Resilient Flooring Manufacturers Institute (ERFMI) who outlined process developments for recovering end-of-life flooring waste and producing secondary phthalate-free PVC, thus preventing usable resources from landfill and/or incineration. ERFMI members recycled 120,000 tonnes of waste PVC flooring in 2021.

Speakers on the business case for addressing sustainability included Andrew Petersen, CEO of the Business Council for Sustainable Development Australia who Australia, who used his thought-provoking presentation to challenge delegates with the question: “Do we need to stop making profit from creating problems for people on this planet, and instead start making profitable solutions?”

One of the additional highlights from the event was prominent futurist Gihan Perera’s keynote address, who entertained and engaged delegates for over an hour as he examined trends and innovations following the Covid-19 pandemic, lessons and skills to be “fit for the future” and key questions businesses should be asking themselves moving forward.

Summing up, Matthew Hoyne reflected: “It’s been four years, but our in-person event has provided inspirational insights and invaluable networking opportunities that will increase understanding and collaboration in our ongoing transition to vinyl sustainability.”

Andrew Petersen added: “PVC AUS 2022 is an important gathering of business, think tanks and government to discuss and explore the practical business solutions that the industry can make to a net zero, and circular and inclusive future Australian economy.”

In addition to the wide range of expert speakers and presentations, PVC AUS 2022 also included valuable networking and discussion time for delegates to re-connect after close to four years since the previous in-person conference, as well as opportunity to browse a range of exhibitor tables and the formal VCA Sustainability Awards dinner.

Australia’s PVC manufacturing industry consumes more than A$1 billion of raw materials annually and over A$3 billion of products containing PVC are sold in Australia.

CLICK HERE to view the short video recap of PVC AUS 2022 and check out a few photo highlights below: