Banksia Awards: ‘PVC a good material for a circular economy’

The 2017 Banksia Award Judges have released their assessments of the PVC Recycling in Hospitals Program initiated by the Vinyl Council of Australia.

Describing the scheme as a ‘world first’, the judges praised it as an ‘excellent case study of an industry's response to keeping its social license’ and ‘embracing product stewardship’ as its means to achieve that.

The PVC Recycling in Hospitals Program was one of five Australian finalists for the Circular Economy category at the Awards night in November 2017. While not winning against tough competition in this category, the extremely positive feedback from the judges on our award submission has given the Vinyl Council of Australia team much encouragement to take this successful medical plastic recycling scheme - now operational in more than 120 hospitals in Australia and New Zealand - to even greater heights. The scheme is aiming to recycle a total of 2,500 tonnes per year throughout Australia.

They also commended the ‘good leadership shown by the health industry and good collaboration between industries’, as well as recognising ‘good circularity – PVC is a good material for a circular economy’.

Established in 2009, the program has overcome challenges to divert quality PVC from landfill. Two Vinyl Council members, Baxter Healthcare (multinational and Australian-based manufacturer of IV bags) and Welvic Australia (Australian compounder), collect and recycle IV bags, oxygen masks and oxygen tubing. These are turned into into durable, locally-manufactured products such as industrial and garden hose and children’s playground mats.

Recognising this, the judges stated: “The program stands out as a unique solution taking a waste stream that would historically go to landfill and re-purposing it thus preventing virgin components required for new products.

“The issue of plastics and chemical use in hospitals is enormous and the lack of sustainability focus in that sector is well-known. Seeing a project that brings change to that sort of culture is great. Overall it’s an innovative solution filling a niche that can be expanded globally and sets an example.”

Vinyl Council Chief Executive Sophi MacMillan comments: “We appreciate this valuable feedback and agree completely with the judges’ view that there is much potential to scale this and expand it across other industries. Watch this space!”

PVC Recycling in Hospitals scheme shortlisted for Circular Economy award

The Vinyl Council of Australia’s hugely-successful hospitals’ recycling scheme has been shortlisted in the Circular Economy category of the Banksia Foundation Awards 2017.

From its earliest beginnings in 2009, the scheme has overcome challenges to embrace more than 80 hospitals in Australia and 28 in New Zealand. IV bags, face masks and oxygen tubing are collected and recycled by two Vinyl Council members Baxter (multinational and Australian-based manufacturer of IV bags) and Welvic (Australian compounder).

Significant investment and commitment by these two companies and the Council has helped the PVC Recycling in Hospitals scheme to flourish and divert quality PVC from landfill into durable, locally-manufactured products. These include industrial and garden hose in Australia and children’s playground mats in New Zealand, which are exported to Australia and around the Pacific.

It is also being replicated round the world. For example, in the UK 11 hospitals are participating in the growing RecoMed PVC recycling scheme with high-quality medical grade plastic being recycled into horticultural products.

The Vinyl Council’s PVC Recycling Project Manager, Helen Millicer said: “We are thrilled to have been shortlisted for this sustainability award. In terms of significance, this Australian initiative shows that quality material from hospitals can be safely recovered and reprocessed to become durable, locally-made product in Australia and in other parts of the world.

“There is no limit to the demand for this high-quality material as a substitute for virgin in Australia and New Zealand. It’s a great step forward in terms of sustainability for PVC and the environment. It’s a valuable raw material resource that can be given a useful ‘second life’ in new products and that’s good news all round!”

The scheme is aiming to recycle a total of 2,500 tonnes per year throughout Australia. Currently, monthly PVC quantities from both hospitals and home patients (Australia & New Zealand) produces enough for 95 km of garden hose or 4500 cushioned play mats for children’s playgrounds. This displaces 14 tonnes a month of imported PVC resin and additives, and reduces greenhouse gas emissions associated with the PVC in new products by 80 percent.

Winners will be announced at the Banksia Awards ceremony in Sydney on 1 November.

Novel concepts ‘advertise’ innovative ways to recycle waste vinyl

Imaginative end product concepts for using waste PVC advertising banners have been displayed at Waste Expo Australia, a business-to-business exhibition for waste, recycling and sustainability in Australia.

Roof shingles, pallet slip sheets, floor tiles and a design for a water storage/seat for garden drip irrigation were among the inspirational ideas presented by Monash University at the event, held from 11 to 12 October 2017 in Melbourne.

The designs were created after the Vinyl Council successfully obtained funding from the NSW Environment Trust to identify ways to reprocess advertising billboard skins and find potential end markets for the recyclate.

Currently around 500 tonnes of this material are disposed to landfill each year, as well as larger quantities of grain covers and truck tarpaulins totalling around 5,000 tonnes per year.

Commenting on the designs, Vinyl Council Chief Executive Sophi MacMillan said: “A series of workshops and forums with the Outdoor Media industry, Monash University, UNSW and manufacturers have delivered excellent results.

“As well as producing some fabulous ideas for recycled PVC, the concepts reflect perfectly the Waste Expo principles of ‘Where today’s waste becomes tomorrow’s future’.”

Other ideas for using the reprocessed material include a woven fabric for should bags, skateboard skins and sound attenuation barriers.

Finding solutions to reprocessing the waste PVC involved close collaboration between industry associations, manufacturers, industrial designers and chemical engineers.

“As a priority recycling area, we are very encouraged by these early results,” added Sophi. “A new reprocessing method has been identified, which is proceeding to international patent, and a low-cost reprocessing method has been identified for some suitable product, leading to 2 tonnes recycled material per month.”

In Healthcare - PVC Recycling in Hospitals

PVC Recycling in Hospitals

The PVC Recycling in Hospitals program collects specific, used PVC medical products for recycling safely into useful new products.

Initiated in Australia by the Vinyl Council in collaboration with staff at a metropolitan hospital, the program collects PVC IV bags, face masks and oxygen tubing it is now operating in over 280 hospitals and healthcare facilities in Australia and New Zealand.

These PVC, or vinyl, medical products are readily recyclable due to the quality and transparency of the polymer and the large number of items in use daily. Over 50 million IV bags are consumed annually in Australia alone. Together with the face masks and tubing, at least 2,500 tonnes of locally recyclable material is available for collection and reprocessing.

A 300 bed hospital could easily recycle around 2.5 tonnes of these quality PVC products each year.

Plastics are a significant share of hospital general waste currently sent to landfill at a cost to the hospital, and PVC is the most commonly used polymer in medical products.

At the initiative of an anaethetist, the PVC Recycling in Hospitals program started as a pilot program in 2009 at Western Health, Victoria. The Vinyl Council developed the program in collaboration with Western Health, and is proud to support its growth with members including Baxter Healthcare, Welvic Australia and transport companies and government agencies. It has grown to service hospitals in across Australia, and in New Zealand. It is aslo winning awards: 2017 Banksia Foundation Circular Economy Finalist; 2016 Victorian Premier's Sustainability Awards Finalist, and our participating hospitals are winners in the Victorian Awards in 2016 and 2017. Inquiries continue to come from across Australia and the world.

The material is reprocessed by Vinyl Council member, Welvic in Australia and MattaProducts in New Zealand. It is primarily used in new industrial and garden hoses and play and safety mats for children and workplaces.

Each tonne of recycled PVC will replace about one tonne of virgin PVC compound in new products, consuming 80% less energy and reducing carbon emissions.

Start PVC Recycling in Your Hospital

|

Watch these videos to learn how and why to set up your program |

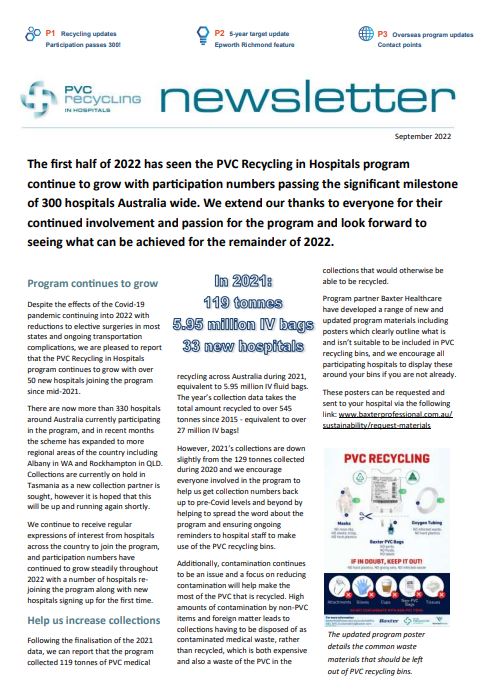

Read Latest Program News:September 2022 Newsletter

July 2021 Newsletter

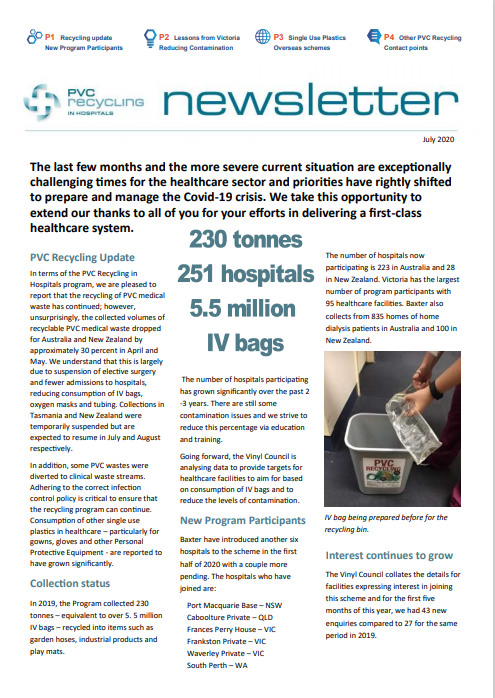

July 2020 Newsletter

Subscribe to Medical Newsletter |

Resources to help set up your PVC Recycling program:The following booklet, training slides, poster and videos have been designed to help hospitals set up and implement PVC Recycling in Hospitals effectively and efficiently. DOWNLOAD the Fact Sheets for staff here DOWNLOAD the Training slides here DOWNLOAD the PVC Recycling Poster here The Business Case for PVC Recycling, prepared by the Victorian Department of Health and Human Services, April 2017. |